From day one, VIP Structures has redefined industrial design and construction by combining in-house architecture, engineering, and building services under one roof. For 50 years, we’ve used pre-engineered metal buildings (PEMBs) to help manufacturers and distributors get operational faster—delivering everything from small warehouses to some of Central New York’s largest, most advanced facilities. It’s all about solving problems, maximizing value, and reducing surprises.

VIP Structures’ Design-Build Legacy in Manufacturing and Warehouse Construction

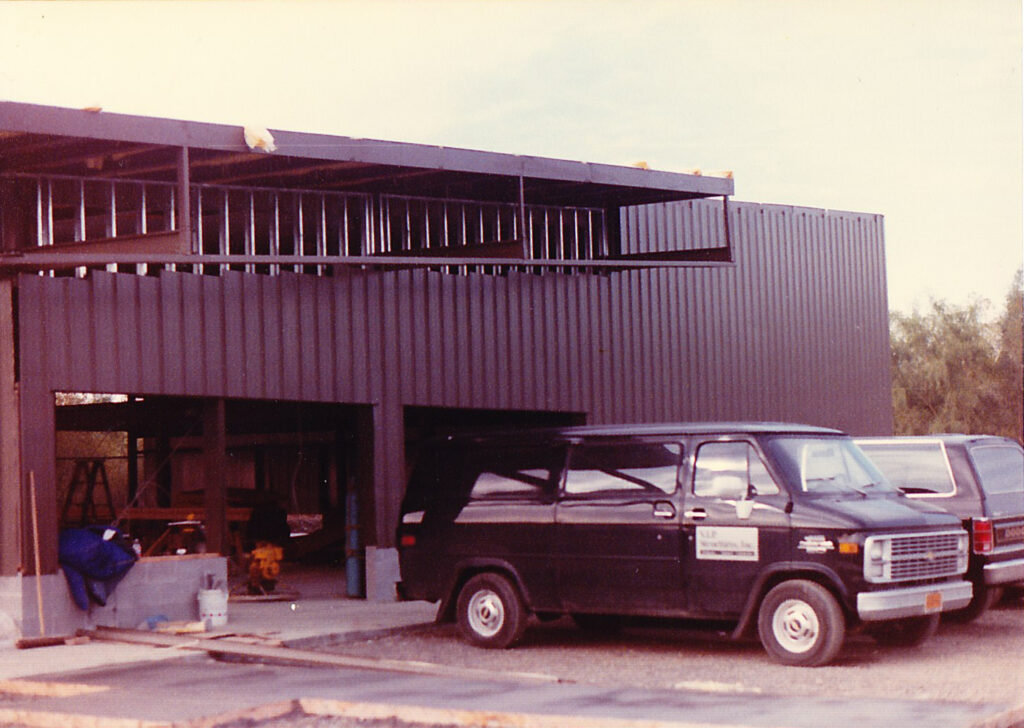

VIP’s extensive work with PEMBs begins with the company’s first project – erecting four PEMBs for Schlitz Brewing Company’s wastewater treatment systems in Syracuse, NY. PEMBs gave VIP a head start, letting the brand-new company deliver industrial buildings without needing a massive employee base. It was the perfect system for launching a design-build firm that wanted to move fast and do more.

“When VIP was put together in 1975, one of the original owners was a steel erector, which is the reason we focused on PEMBs from inception,” states Dave Nutting, who ran VIP Structures from 1975 to 2021.

VIP’s in-house team became experts at leveraging PEMB systems, always tailoring solutions to what the project actually needed, never more, never less. This practice helped VIP grow rapidly in industrial work, moving from small PEMBs to hundreds of thousands of square feet.

VIP’s in-house team became experts at leveraging PEMB systems, always tailoring solutions to what the project actually needed, never more, never less. This practice helped VIP grow rapidly in industrial work, moving from small PEMBs to hundreds of thousands of square feet.

PEMB Innovation: Saving Time and Cost with Holistic Design-Build Solutions

In the early years, many PEMBs were simple boxes, warehouses, or storage buildings. However, as VIP expanded, the design-build team continued to push these systems further. Whether building a distribution center or a manufacturing plant designed for heavy equipment loads, VIP’s architects and builders continued to utilize PEMBs in more innovative and creative ways, often blending conventional with pre-engineered systems to deliver the best solution for each client and maximize efficiency while preserving the flexibility needed for future operational needs. VIPs’ need for flexibility and engineering horsepower to support this integrated thinking was met with premier pre-engineered metal building fabricator Varco Pruden, marking the hallmark of their 50-year partnership.

“One of the most complex projects we completed using a PEMB was the construction of four recycled paper mill facilities,” says Jim Herr, VIP Vice-President and a 45-year company veteran.

Traditionally, multi-floor paper mills would be built entirely with conventional steel. But starting in the early 90s, VIP worked closely with Varco Pruden to create a hybrid approach—designing a PEMB system that sat on top of a heavy conventional steel framework for the elevated operating floors.

“Even with the PEMB supporting massive bridge cranes, some as large as 100 tons, this hybrid strategy delivered significant cost savings for our clients,” Herr explains. “It helped control initial investment and made it possible for a startup to launch—and ultimately become an industry leader that’s still thriving today.”

A Partnership Built on Flexibility, Problem Solving, and Finding a Better Way

From VIP’s first days of erecting a Varco Pruden PEMB at the Schlitz Brewery to more than 50 years of shared projects, the VIP-Varco Pruden partnership has thrived on shared values: collaboration, adaptability, and a commitment to doing what is best for the client.

VIP often worked directly with Varco Pruden’s engineers—exploring dozens of design options to find the most efficient solution. And Varco Pruden was eager to run the numbers, refine the designs, and work together every step of the way.

“Varco Pruden stood out because of their willingness to customize and engineer exactly what we needed,” Nutting says. “Other manufacturers had preset frames. The Varco Pruden team would take our snow loads, wind loads, spans—whatever it was—and engineer each building precisely. That meant we could deliver lighter steel, less waste, and faster schedules.”

Over the years, VIP earned Preferred Builder status with Varco Pruden, received multiple national awards for PEMB design and construction, and saw Nutting serve on Varco Pruden’s President’s Advisory Committee.

The VIP–Varco Pruden relationship stands as a clear example of what’s possible when two teams share a commitment to flexibility, engineering excellence, and putting clients first. This partnership has not only shaped how complex industrial and manufacturing facilities can be delivered across Central New York but continues to set the standard for collaboration and innovation in the pre-engineered metal building industry.

For 50 years, VIP and Varco Pruden have redefined what pre-engineered metal buildings can be — not off-the-shelf boxes, but precision-engineered solutions tailored to each client’s exact needs. It’s a partnership built on innovation, flexibility, and always finding the smartest way forward.

VIP: Central NY’s Trusted Industrial Design-Build & PEMB Experts

The PEMBs of today are more versatile, precise, and energy-efficient than ever. And VIP continues to be a leader, designing and building PEMBs to support a wide variety of uses such as manufacturing facilities, food processing plants, large warehouses and distribution centers, and recreation centers.

“PEMBs are a phenomenal tool for industrial and warehouse clients who want speed and cost control when building a project,” says Meg Tidd, CEO of VIP Structures, “but what really drives their exceptional value is how adaptable they are when operational needs change over time. This allows clients to adjust quickly and easily to meet the latest market or product demand.”

As VIP marks 50 years, its track record with pre-engineered metal buildings, and long partnerships with trusted partners, stands as proof of what’s possible when teams collaborate, adapt, and keep the focus on solving client problems.

“We’re incredibly proud of everything we’ve built over the years,” says Tidd. “But we wouldn’t have been able to do any of it without the trust our clients have placed in us to tackle their most complex industrial and manufacturing projects. We’re excited to see what the next 50 years brings to the CNY landscape.”

Whether it’s Varco Pruden or another system, the VIP philosophy stays the same: choose the right solution, think holistically, and always design with the client’s best interests in mind. It’s this adaptable, collaborative, and value-driven approach that’s earned VIP Structures a reputation as the go-to team for industrial design and construction across Upstate New York and beyond.

Partner with VIP Structures, the industrial design-build and pre-engineered metal building experts trusted for over 50 years to deliver projects faster, smarter, and with fewer surprises.